Fleece Covers

Foundation

The GlacierAlive Foundation supported the project to implement micro-free fleece (PLA fleece) in 2025.

100%

recycled material.

10 years

of successful use on the Diavolezza glacier.

Fleece Covers

Foundation

The GlacierAlive Foundation supported the project to implement micro-free fleece (PLA fleece) in 2025.

100%

recycled material.

10 years

of successful use on the Diavolezza glacier.

Fleece Covers

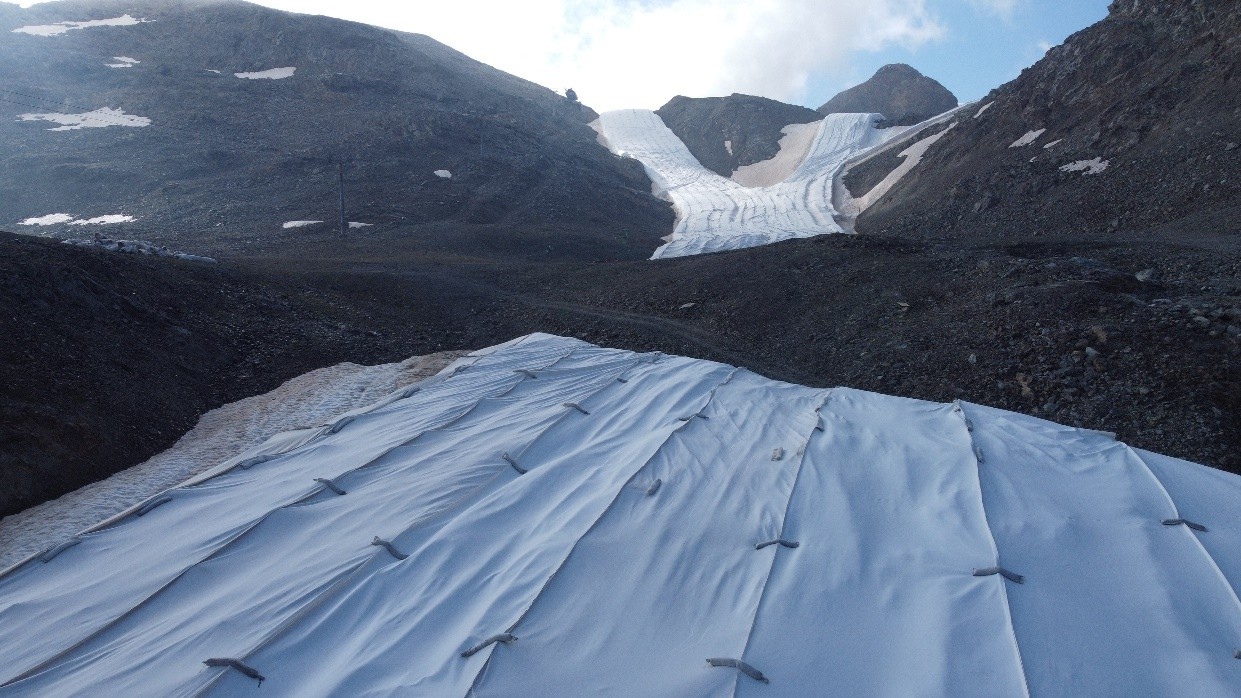

Glacier covers have been used in Swiss ski resorts since 2005 to protect the infrastructure needed for skiing (glacier access, training slopes in autumn). The glacier and snow surfaces are covered in May and the covers are removed at the beginning of autumn (late August/early September). Covering the snow and ice surfaces can reduce melting by up to 60%. However, due to the polypropylene (PP) material used, this type of snow and ice conservation has come under criticism as it contributes to microplastic pollution in high mountain areas.

For example, after being covered with a fleece for 10 years, the Diavolezza glacier has become about 10 meters thicker instead of shrinking. Even today, the glacier is still partially covered during the summer months to protect it from further melting.

Thanks to the generous commitment of Mastercard Switzerland, the GlaciersAlive Foundation was able to set up a test facility for glacier covers in January 2022. The aim is to test different materials and methods so that glacier covers can be installed with fewer emissions in terms of microplastics and mechanical use.

The newly developed covers made of microplastic-free PLA material* measuring over 20,000 m² was produced in spring 2025 and delivered to five different mountain railway companies that protect glacier areas or engage in snow farming. We expect to receive feedback in fall 2025. It is therefore not out of the question that even lost glaciers could be brought back to life, as is happening on the Diavolezza.

Testfläche mit mikroplastikfreien PLA (Vordergrund) auf der Diavolezza (Bild: Felix Keller)

PLA falls under the category of synthetic polymers, as the material is produced artificially in a laboratory. Unlike conventional plastic, PLA is considered a “bioplastic” because it is produced from renewable raw materials: PLA consists of corn starch and lactic acid and thus meets the criteria for renewable biomass. The manufactured molecular structure of PLA is biodegradable and compostable..

Are you interested in this project and would like to support it? Here you can make an important contribution with your donation.